Ultraviolet (UV) curing is a technology that is used to rapidly cure industrial coatings. Chemical coatings utilizing UV curing for tube and pipe products are gaining popularity as an alternative to traditional thermal curing due to speed, energy efficiency, and environmental benefits.

There are three main methods used to cure UV coatings in the tube and pipe industry:

All three systems accomplish the same end result: coating polymerization by emitting ultraviolet radiation.

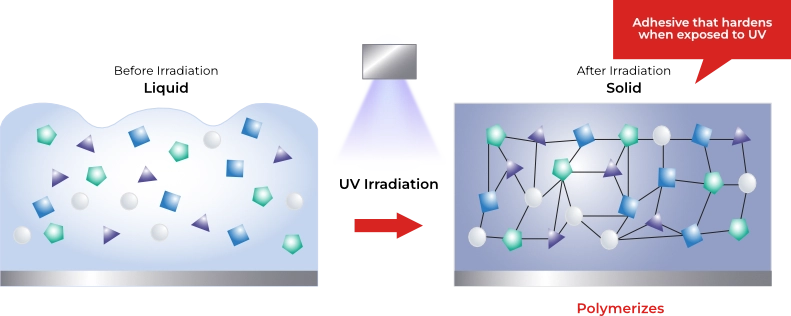

UV Cure Theory

The curing process begins when UV light is emitted from a lamp at a determined wavelength, penetrating the layers of coatings applied to a substrate. Once exposed to this light, photo initiators contained within the coating breaks down, generating free radicals that trigger a chain reaction among the polymers.

This immediately prompts polymerization that converts the liquid to a durable solid. This conversion occurs rapidly, often in mere seconds, thus allowing for instant curing and handling. This is a stark contrast to traditional methods that take hours, if not days, to fully cure.

As manufacturers strive for higher efficiency and productivity, the application of UV curing continues to expand, positioning itself at the forefront of modern technology.

Arc Lamp Curing Systems

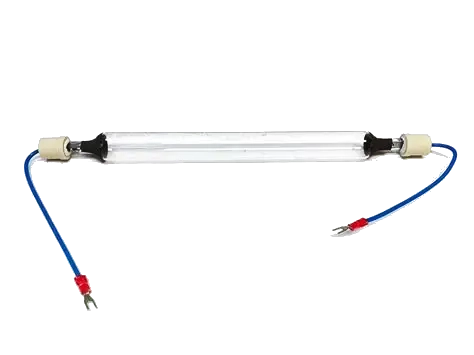

Arc Lamp Systems utilize a quartz glass tube, filled usually with mercury gas. This gas is ignited by an electrical arc discharge. This method represents the most cost-effective UV curing system. It covers a wide spectrum of curing wavelengths (200-400 nanometers), making it ideal for a wide range of coating types and formulations.

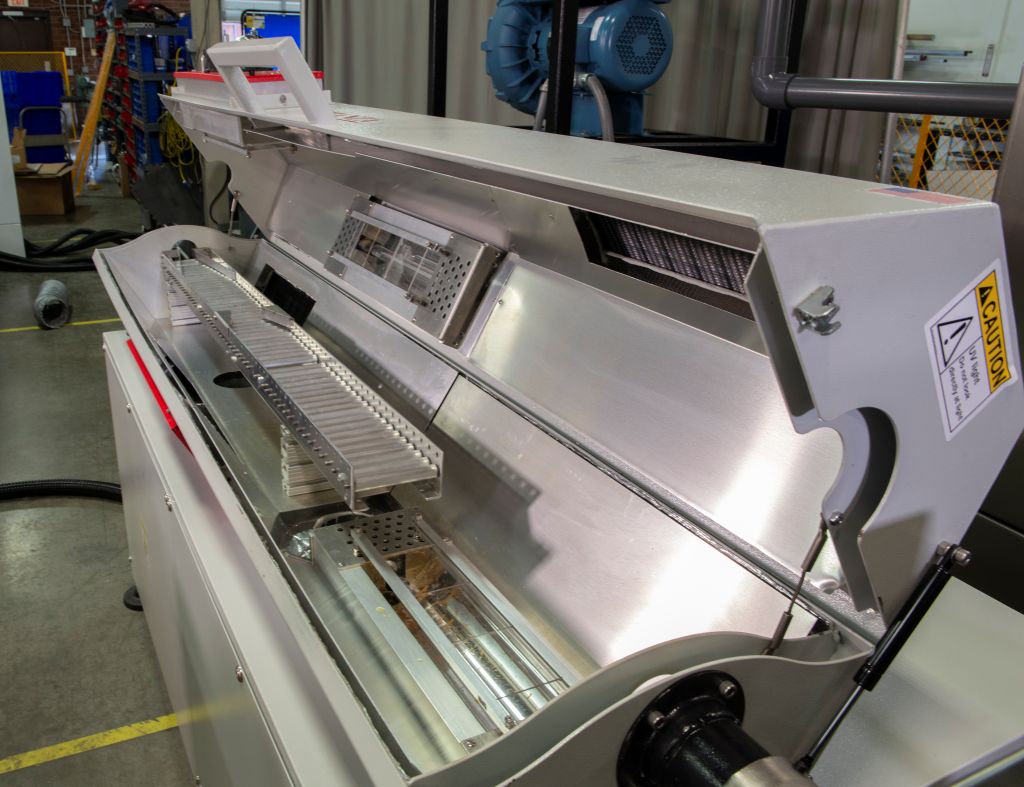

The arc lamps are typically mounted to the interior of an enclosed case designed to incorporate exhaust and cooling. The number of lamps is determined by the energy required for the curing process and desired speed. Lamp life can range from 800-1000 hours. Although offering outstanding cost and flexibility, they are the only method wherein the lamp degrades with use, requiring monitoring and replacement as output declines.

Microwave Lamp Curing Systems

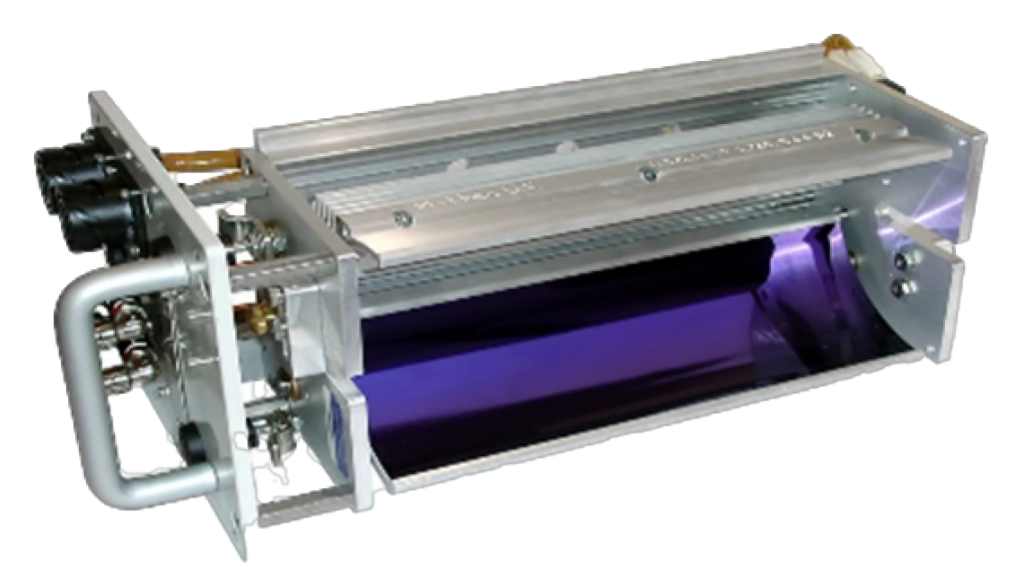

Microwave Lamp Systems utilize a quartz glass tube, usually filled with mercury gas. The gas is ignited by microwave energy, as opposed to an electrode in Arc Lamps. This method represents an intermediate cost UV curing system. It covers a wide spectrum of curing wavelengths (200-400 nanometers), making it ideal for a wide range of coating types and formulations.

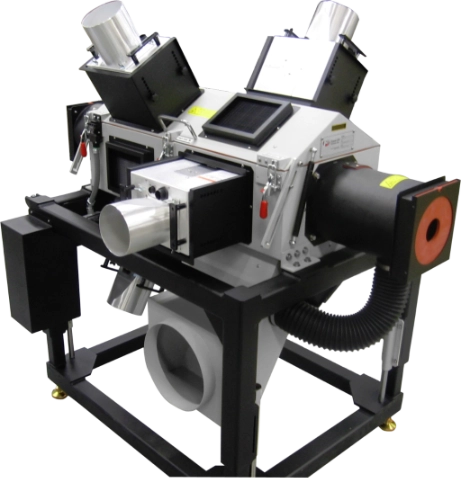

The number of Microwave lamps used are determined by the energy required for the curing process and the desired speed. These lamps are typically mounted to the interior of a Light Shield, a specially designed case that utilizes exhaust and cooling. This Light Shield is more sophisticated and more costly than the Arc Lamp case.

The Microwave design is moderate in cost, but offers users the important benefit of maintaining full lamp power over 8,000-10,000 hours before needing replacement. This lamp life and sustainable output require less lamp maintenance overall and should be part of the factors considered in the machine ROI.

LED Curing Systems

Light Emitting Diode (LED) Curing represents the most recent and technologically advanced addition to the UV curing market. It utilizes LED technology to emit a single wavelength, typically 390 nanometers, that can be matched to photo initiators in the coating chemistry to cure. It can offer substantial environmental benefits in energy usage, as well as full output throughout its long-life, up to 20,000 hours. LEDs operate at a cooler temperature than lamps, offering advantages to some materials.

Along with the important advantages of LED technology, these systems can also pose significant challenges. As a new technology, the coating supply chain is limited and expensive. Additionally, the single wavelength LED output restricts surface cure and requires special chemistry. The maintenance factor, at this point, appears high. Replacement LED units cost substantially more, and are less available than the more economical UV lamp selections.

Despite the current challenges, LED UV curing is an increasingly important part of the future. As coating and LED technology develops, and with a more substantial field history, the picture on LED UV curing will become more accurate. Until then, this technology should be evaluated on a case-by-case basis for each application.

Conclusion

Choosing a method of UV curing for tube and pipe coating production is not a “one size fits all” decision. Each system offers advantages and disadvantages to the manufacturer. Each manufacturer must evaluate a myriad of technical and business factors, including:

- Capital equipment costs, including ROI

- Coating costs and performance specifications

- Long term maintenance costs

- Plant realities of space, power, and personnel

To ensure that you make the correct choice, please reach out to your Stanza Machinery Sales Engineer. We will assist you with evaluating your options and aid in understanding the best method of UV curing for your company’s needs.