When approaching factory priming and finishing it is best practice for siding, decking, and thermally modified wood* to have a pre-stained/prime or treated finish applied prior to shipment and installation. This serves a three-fold purpose:

- Seals all surfaces to protect from moisture intrusions and degradation during shipment, warehousing, and especially on-site where exposure can be potentially severe.

- Ensures that all sides, but especially the back of the siding (known as back priming), is pre-sealed prior to installation, serving as a moisture barrier against the surface it is applied to.

- Decreases the number of coats, and therefore labor, required in the field to finish.

*Wood that is treated with high heat and steam in the absence of oxygen resulting a structural and chemical change in the wood. The resulting “modified” wood is extremely resistant to decay and highly stable for exterior environments.

Coatings in the Factory Priming and Finishing Process

There is a vast selection of coatings employed in pre-coating siding. Commonly, siding coatings fall into two categories: Penetrating Coatings and Surface Protective Coatings.

Penetrating Coatings are designed to enter into the wood fibers and bond with the wood. This process is also known as impregnation and is best accomplished with a machine that flows coating onto the surface before mechanically brushing it into the wood. Thus it is called a Brush/Flow Coating machine in the US and an Impregnation Machine in Europe.

Surface Protective Coatings, as the name implies, coat the siding with a minimal level of penetration, but still perform as a surface barrier to the elements and degradation. These types of coatings can be applied with spray machines, vacuum coaters, and roll coaters.

Both penetrating and surface coatings varieties can include penetrating oils, water & oil-based stains, alkyd or water-based opaque primes, and specialty coatings (such as those used in fire-proofing). It is of importance that the coatings be selected specifically for the substrate material and performance requirements. Many coatings offer warranties that can be in effect for decades. Each application requires significant discussion with your coating supplier.

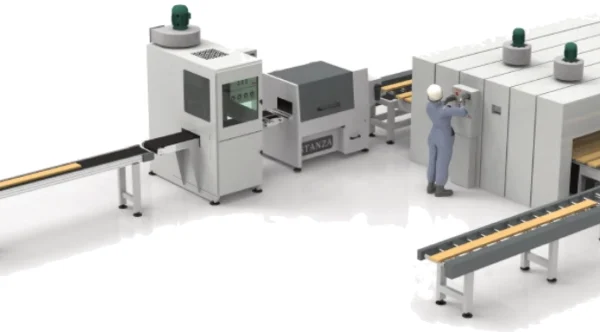

Machinery & Factory Lines

Factory priming and finishing production lines that prime/pre-coat typically address four operations, dictated by their production parameters:

- Infeed Material Handling (with or without denib sanding and cleaning options)

- Coating (brush, vacuum, spray, roll)

- Drying (lateral or in-line oven)

- Material Handling (outfeed to packaging)

The line is initially designed to fit a production output requirement on a range of sizes and widths. This will determine the specifications of the line components and the line layout. Take a look at the example below:

Calculating Production Output

In our example, we’ll use a real-world typical production number for siding:

1″ x 6″ x 16′ = 575 boards per hour

Let’s review the line components for each of the operations listed earlier:

Infeed

Our engineer knows that in order to get 16′ boards x 6″ wide with 4 sides coated at 575 boards per hour, we need to calculate:

575 boards per hour X 18′ length (board length plus 2′ of spacing between boards for feed loading) ÷ 60 min/hr = 172.5 ft/min.

Assuming a plant efficiency factor of 0.85:

172.5 ÷ 0.85 = 202.9 ft/min

This is our feed speed required to achieve the stated 575 boards per hour.

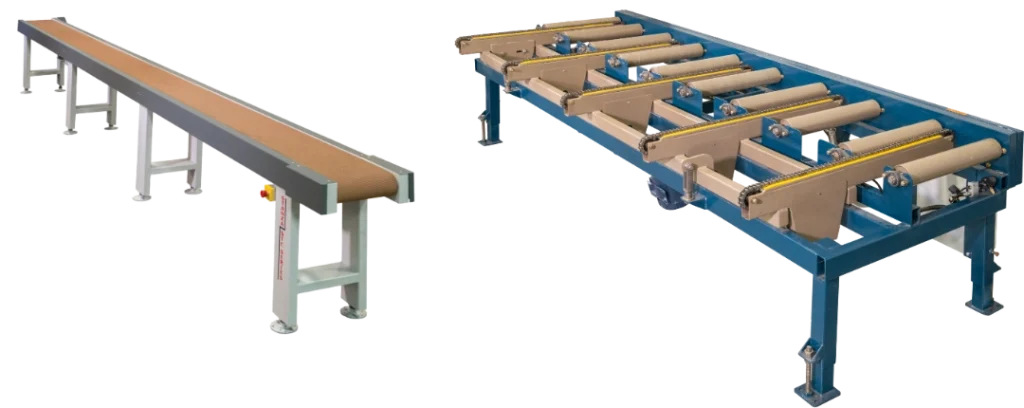

Therefore: Specify infeed conveyor to run at 220 ft/min with a standard width range up to 12″, with a working conveyor length greater than 16′.

Coating Machine

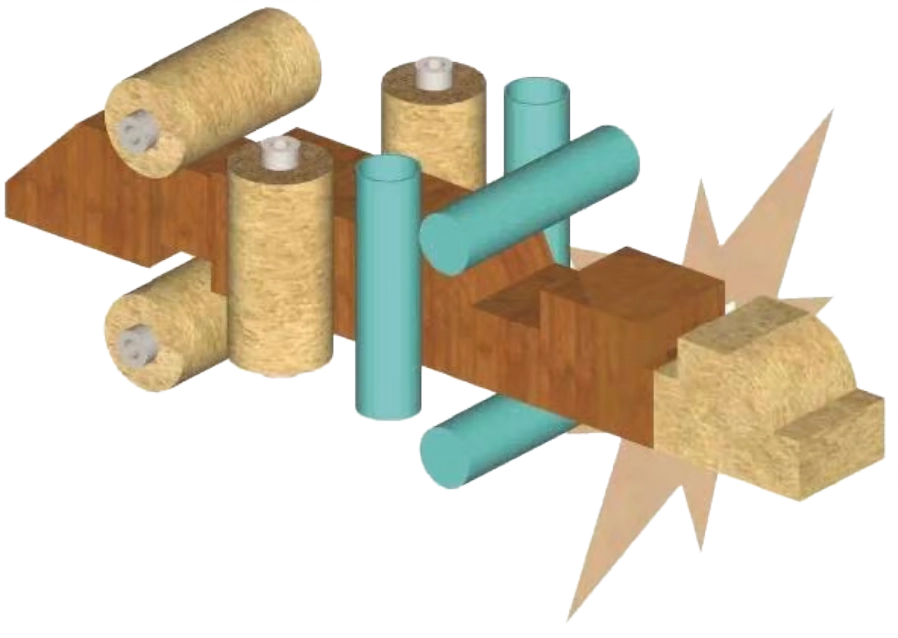

In this scenario we are using a Brush/Flow coater for our coating type.

In order to get the required number of boards, we match the feed of the previous machine at 220 ft/min. The critical specifications for the Brush/Flow Coater are the number and orientations of the brushes and air knives. Our experienced Stanza Engineer determines that in order to run at this speed and with the chosen coating, we need the following system orientation and brush arrangement:

So: specify brush/flow coater speed at 220 ft/min, sized to a 12″ maximum width, with a component orientation of: air knives top & bottom, air knives left & right, Nylon brushes left & right, Tampico brushes top & bottom, with inverter controls to all brushes for speed adjustment.

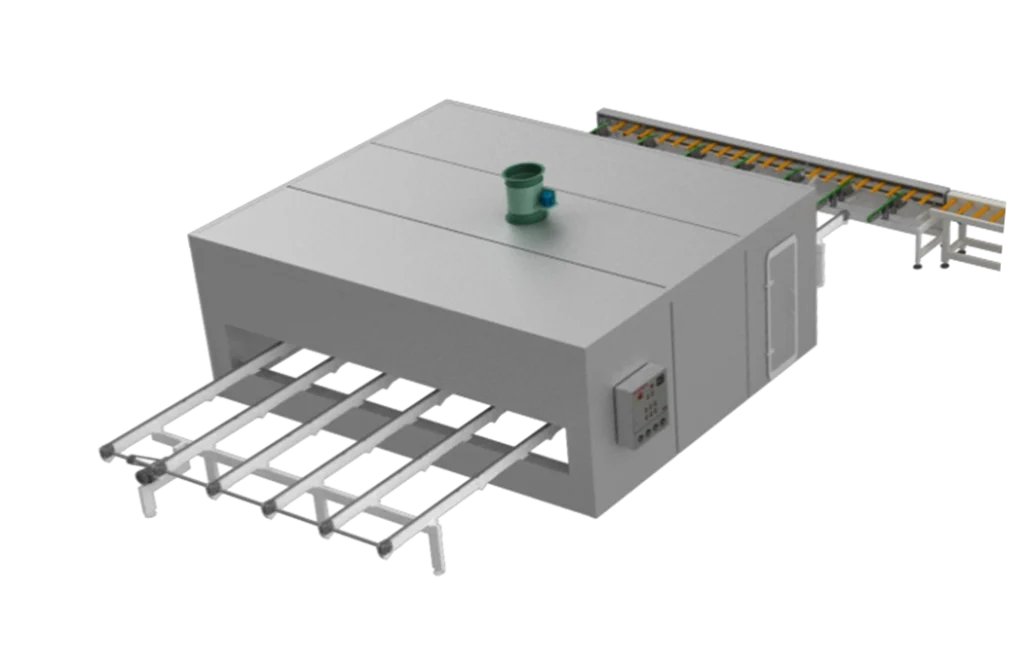

Drying Oven

The drying of coatings applied in the previous process is the most critical operation. It requires drying data from the coating supplier and a properly designed material conveyance that can transport, interval space, and execute precise drying schedules.

In our example, the coating specification is “dry to handle” by the coating supplier. Convection heat is specified for that purpose, dictating a lateral oven design.

This lateral design requires transferring each piece 90° and maintaining intervals necessary for board clearance and drying per the following schedule:

- 1-minute ambient flash

- 2 minutes convection heat at 160°F

- 1 minute ambient cool down

Assuming our 16′ board is moving at 220 ft/min, our engineer must size the oven and maintain the process flow while making the lateral transfer of the board without crashing the system.

Her calculations take into account the following factors:

- Board length

- Nominal speeds and accelerations

- Gap to oven transfer requirement

- Oven chain deck speed

- Oven dwell time

- Oven length

As a result: the oven should be specified with a lateral transfer infeed unit, chain deck unit, and convection oven top capable of a minimum of 160°F, with a total length of 40′ to accomplish 4 minutes of dry schedule.

Material Handling Outfeed

The outfeed material handling systems are designed for downstream processing requirements that include transfers, board flippers, packaging, etc. These can be added to our example basic system.

View the material handling video for best systems:

Summary

Line layout and machine specifications for the priming and precoating of siding, decking, and thermally modified wood requires a detailed analysis of extensive features. Stanza Machinery has the tools, experience and expertise to help guide you through this process. Call us today for a consultation.