Vacuum Coating Head Arrangements: A Simple Overview

There are many arrangements of vacuum coating heads, each tailored to specific applications. However, they generally fall into three main categories based on fluid delivery, circulation, and the return of excess coating from the head to the vacuum tower.

Vacuum Coating Head Varieties

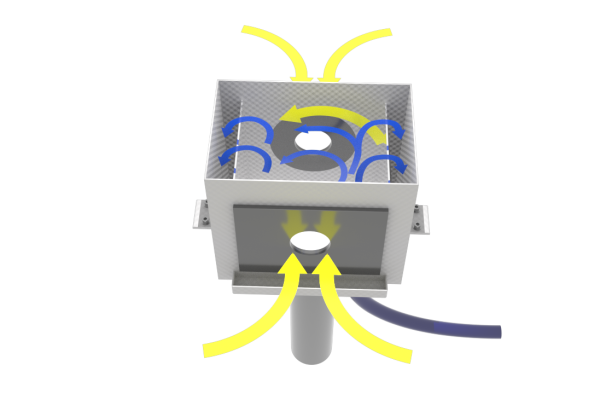

Weir Head

This is the original (or classic) head design. Coating is pumped into the bottom of the head and vacuum is then applied, creating the characteristic whirlpool effect inside the head. Excess coating is recirculated by being pulled over the weirs by the vacuum and directed back to the tower (see Fig. 1).

Fig. 1: Weir Head

Advantages

- Excellent coverage over the entire part

- The head holds a large volume of coating, ensuring maximum wetting and coverage

- Highly flexible and works with many varieties of coatings (water-based, UV-curable, etc.)

Disadvantages

- The large volume of coating in the head requires very precise control of vacuum level and fluid flow to prevent the overloading of baffles and filters in the vacuum tower

- Risk of clogging vacuum producers or allowing coating mist to escape into the environment

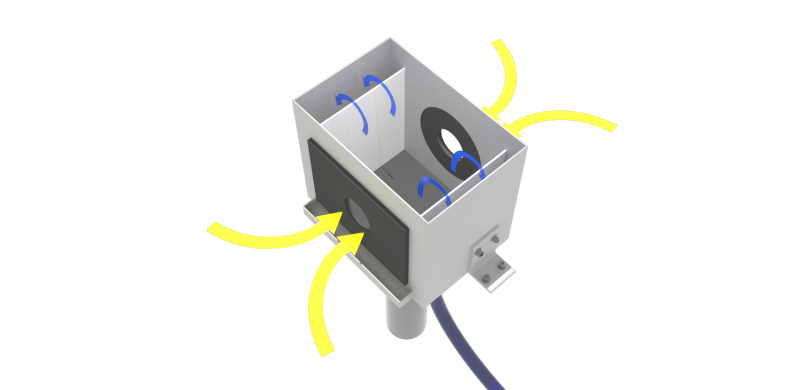

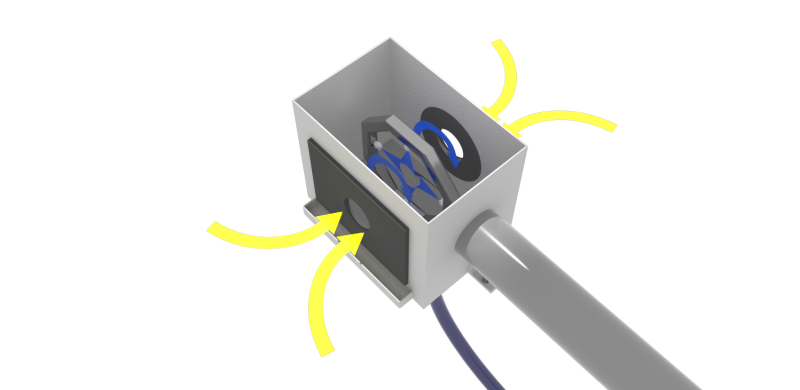

Ring and Nozzle Heads

These types of heads use nozzles, rings, jets, or other similar devices to apply coating more precisely to the substrate surface. Excess coating is removed via bottom drainage and a dedicated vacuum port that captures atomized excesses. Both the drain and the vacuum port return remaining coating to the vacuum tower for separation and filtering (see Fig. 2)

Fig. 2: Ring/Nozzle Head

Advantages

- Delivers a precise, controlled amount of coating, dramatically reducing the volume that requires separation and filtration

- Lower maintenance due to reduced filter and pump clogging

- Allows for significantly higher line speeds as excess coating is more easily and efficiently managed compared to the weir method

Disadvantages

- Part geometry must be carefully analyzed for each application, reducing overall flexibility

- Nozzles can become clogged and fast-drying coatings are often difficult or impossible to use

- Higher maintenance at the point of application, (nozzle cleaning, etc.) is inevitable

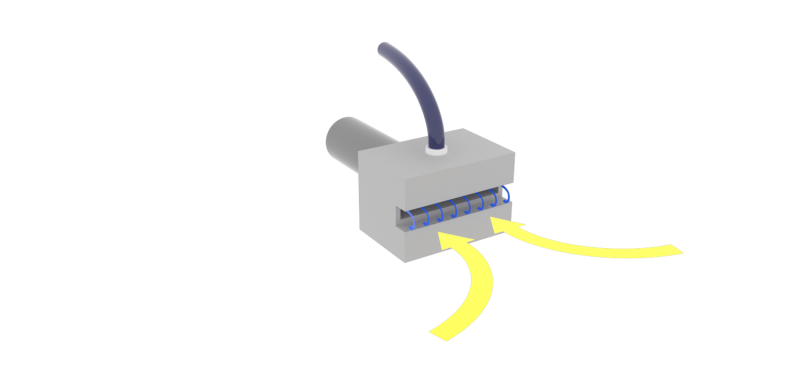

Selective Remote Heads

These highly specialized vacuum heads are designed to coat very small or specific sections of parts, similar to pin-striping. Each small head is custom machined to the reverse profile of the part and is typically mounted remotely, often on a separate machine or robotic platform. Multiple remote heads can be used to cover different selected areas of the same part (see Fig. 3).

Fig: 3 Selective Remote Head

Advantages

- Enables coating of areas that cannot be reliable coated by micro-spray, masking, or other methods

- Very high transfer efficiency due to the vacuum process

Disadvantages

- Heads are single-purpose and expensive to design and manufacture

- Controlling coating volume and consistency in such small heads can be challenging

Conclusion

Choosing the vacuum coating head arrangement that is the best fit for your application requires a detailed analysis of part geometry, production requirements, coating type, and line speed. The engineers at Stanza Machinery are available to assist in evaluating these factors and recommend the optimum solution for your specific needs.

For more information about Vacuum Coating check out this article:

Vacuum Coating: The Winning Strategy in Tube and Pipe Manufacturing | Stanza Machinery

Contact one of our Specialists today!