Technology Rooted in History?

Roll coating is an ideal method to apply uniform, thin layers of finish materials to flat metal, wood, and plastic substrates.

This technique is based on an ancient method; transferring a layer of coating from the surface of a roller to the flat plane of a substrate surface.

Today’s modern roll coating technology gives us a highly effective method that is both precise in application and environmentally friendly, offering nearly 100% transfer efficiency.

The most common type of modern roll coater is the differential direct style. This type of coater features moving components that can be individually adjusted in speed and direction. This ensures maximum control of the coating process resulting in maximum quality and efficiency.

Roll Coating Machine Components

The process of transferring a layer of coating from the roll requires several key components:

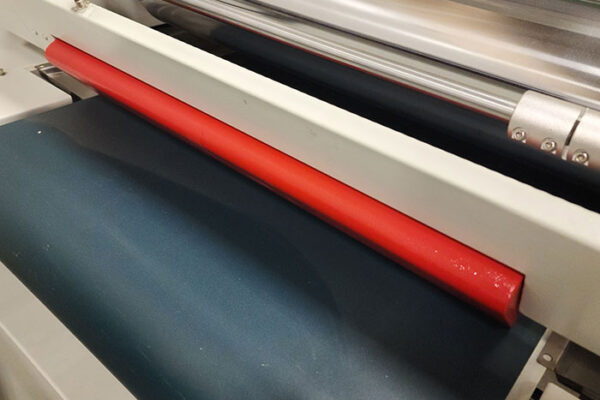

The conveyor belt, or roll system moves the substrate under the application roll, enabling the film transfer.

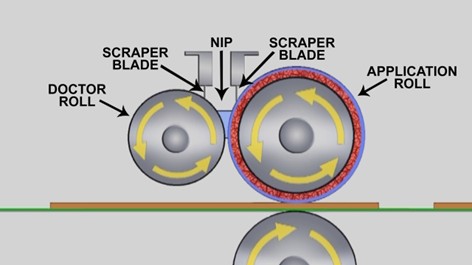

The application roll carries the coating film, which will be transferred to the substrate upon contact. The application roll is covered with a variety of materials such as rubber, polyurethane, and sponge. The type of roll covering depends on the coating material and application requirements. This piece works in conjunction with the metal doctor (metering) roll to form a pocket of coating, called the nip, that wets the application roller.

In order to control the film thickness on the application roll, the gap distance between the doctor roll and the application roll is adjusting, determining the size of the nip. This regulates the amount of coating applied to the application roll and therefore transferred to the substrate. Additionally, the speeds and rotations of each roll are adjusted for precise control of coating thickness and laydown.

Scraper blades are utilized on both the application and doctor rolls. Their function is to clean the rotating rolls, enabling fresh coating to be applied and to keep coating from falling onto the conveyor when run forward.

Finally, a recirculation fluid pump pulls coating from a container and pumps it slowly between the rollers into the nip, ensuring that a clean, uniform supply of coating is continuously provided.

Each of the components of a modern roll coating machine requires knowledge and understanding to accurately set, but when properly achieved, the machine produces a beautiful and accurately coated part.

Learn More

Because roll coating is a dynamic, visual process, setup and operation are best demonstrated. Check out the following video for a practical walkthrough of roll coater operation. For more information and specifications on Stanza Roll Coaters, visit our roll coat page, or contact one of our specialists to assist you with all of your coating needs.